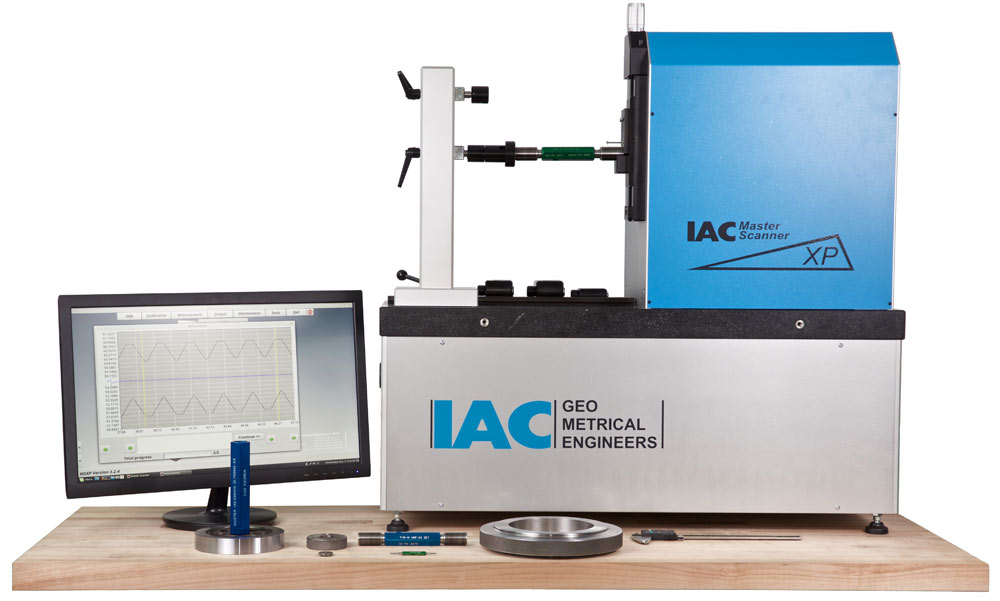

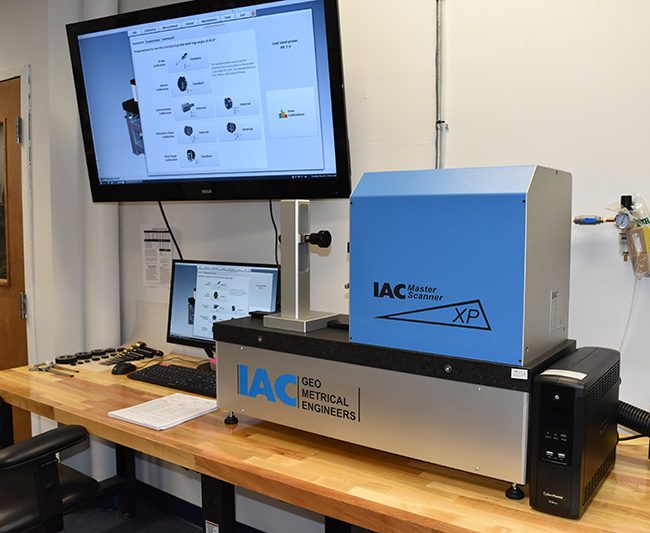

MSXP Series

- 外部测量范围:1.0~50/90mm(取决于型号)

- 内部测量范围:2.5~60/100mm(取决于型号)

- 最大测量长度:25mm 或 60mm(取决于型号)

- 最小螺距:0.1mm

- 重量:150kg

- 900x350mm 花岗岩工作台

- 水平/垂直导轨:精密空气轴承

- 驱动类型:瑞士无刷电机

- 测量系统:海德汉增量式直线光栅尺

- 分辨率:0.01μm

- 带电缆的接口盒

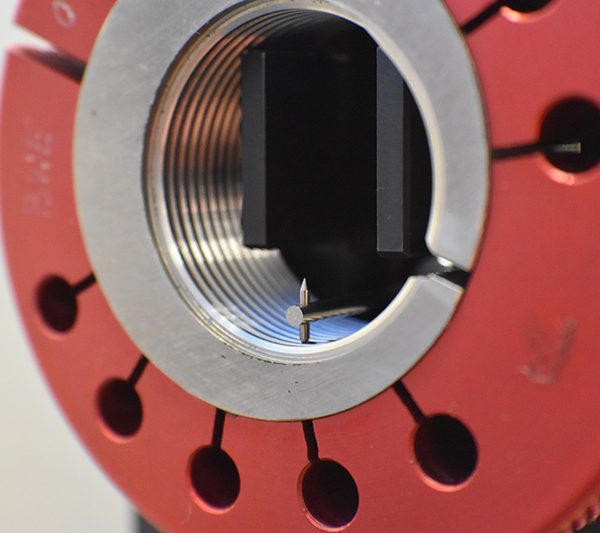

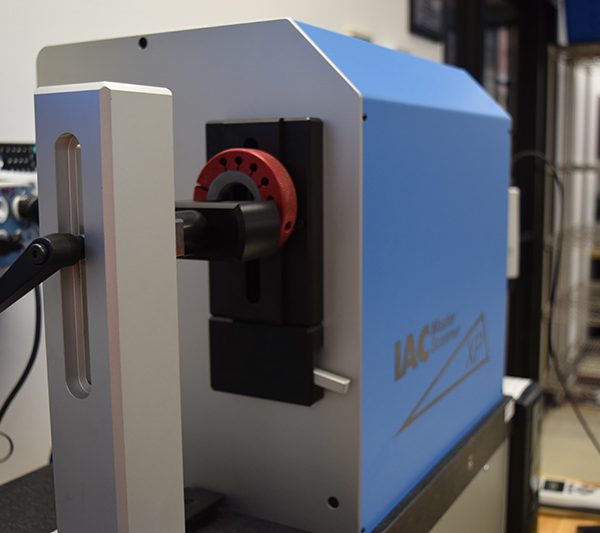

- Click'On 快速更换系统

- 工业控制计算机

- 键盘、鼠标、纯平显示器

- 所购标准校准证书

- 机床轴激光校准证书

- MSProg LINUX 软件包(多语言)

- IACLIB,标准公差库

- 客户验收后保修 1 年

- 1 年MSProg 和购买模块的免费更新

此内容将在所有产品页面之间共享。

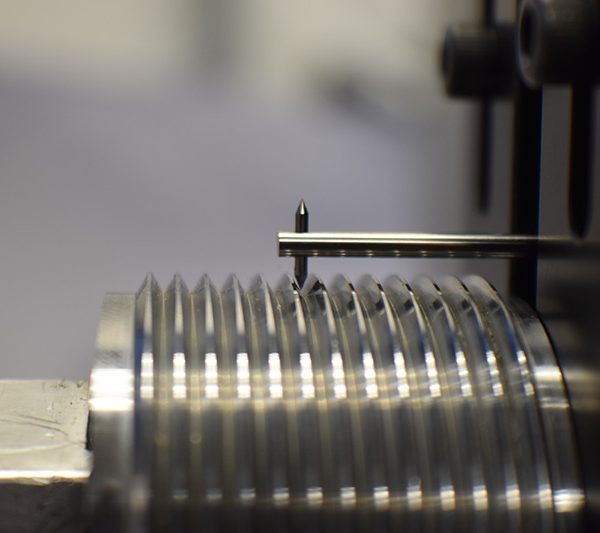

Introducing the Masterscanner MSXP Series, a fully automated measurement solution that operates without any human involvement. In less than two minutes, the machine provides a comprehensive display of all measured thread parameters for each pitch. The system automatically generates a measurement report by comparing the collected data against its integrated library of thread standards. The MasterScanner minimizes the potential for human error while enhancing measurement efficiency, quality, consistency, and accuracy. It adheres to all traceability requirements outlined in ISO-9000 and ISO/IEC 17025:2017.

Obtain detailed measurements for cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges, and various other gauges with internal and external dimensions. This includes virtual pitch diameter, single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half thread angle, flank straightness, lead angle, taper, perpendicularity, and more.