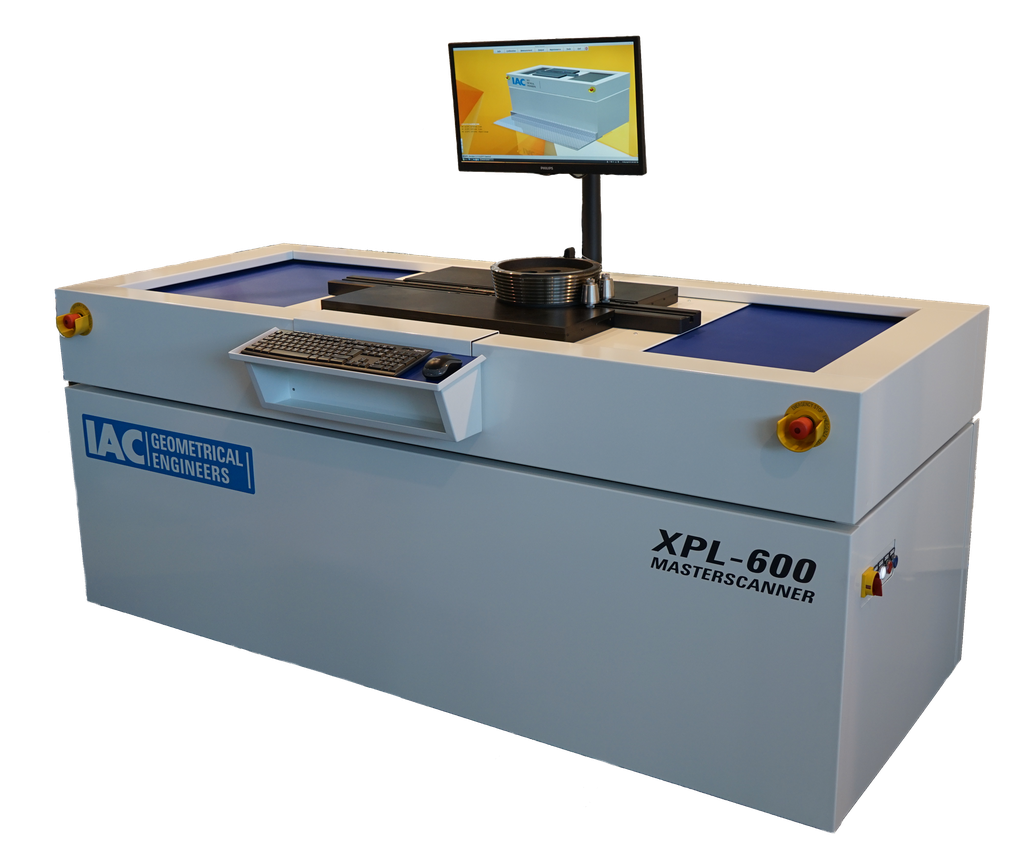

XPL Series

- External measuring range: 1.0~390/490/590mm (model dependent)

- Internal measuring range: 2.5~400/500/600mm (model dependent)

- Max measuring length: 100mm or 200mm (model dependent)

- Min thread pitch: 0.1mm

- Weight: 1100 ~ 1400kg

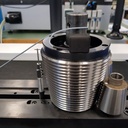

- Granite bed

- Horizontal/Vertical guidance: Precision air bearing

- Driving type: Swiss Brushless motor

- Measuring system: Heidenhain incremental linear encoder system

- Resolution: 0.01μm

- Interface box with cables

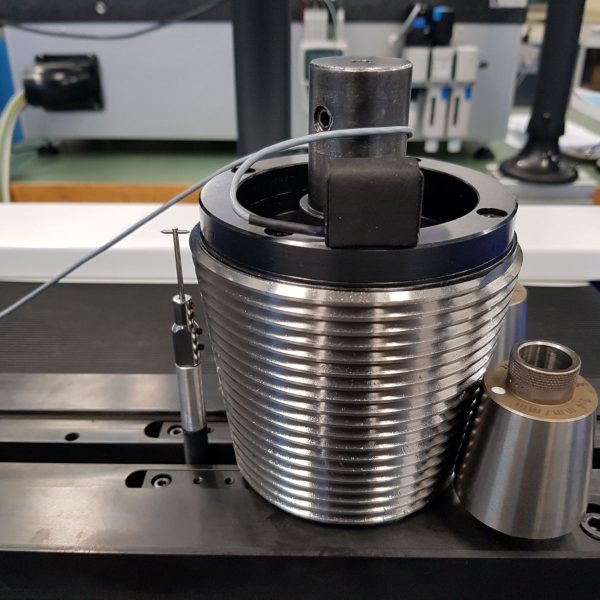

- Click'On quick-change system,

- Industrial Control Computer

- keyboard, mouse, flat screen

- Calibration Certificates of the purchased standards

- Laser calibration Certificates of the machine axis

- MSProg LINUX software package (Multi-Language)

- IACLIB, standard tolerance library

- 1 year warranty after inspection acceptance by the customer

- 1 year of free updates of the MSProg and purchased modules

This content will be shared across all product pages.

| Max. Scan Length: 200mm / 7.87inch |

| Temperature Compensation: Included |

| Active Anti-Vibration Damping System: Included |

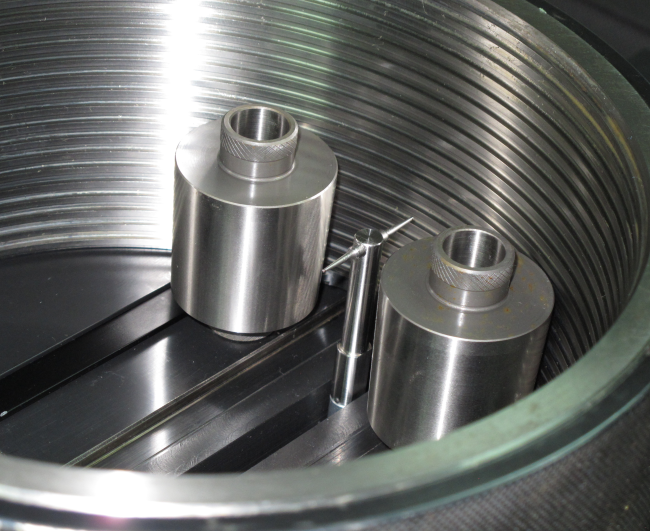

Special manufactured to supply: Gage manufacturers, Oil-, Gas-, Military- and or Aerospace -Industry.

Masterscanner XPL Series Full-automated measurement, without human intervention, the machine displays all measured thread parameters per pitch in under 2 minutes. All measured values are compared with the built-in thread standards library, the system generates the measuring report automatically. The MasterScanner significantly reduces human error, as well as improves the measuring efficiency, quality, consistency and accuracy of the results. The MasterScanner is compliant with all requirements

for tractability of today as stated in ISO-9000 and ISO/IEC 17025:2005.

Get all parameters of cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges and other gauges with internal & external dimensions, including virtual pitch diameter , single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half of thread angle, flank straightness, lead angle, taper, perpendicularity, etc.