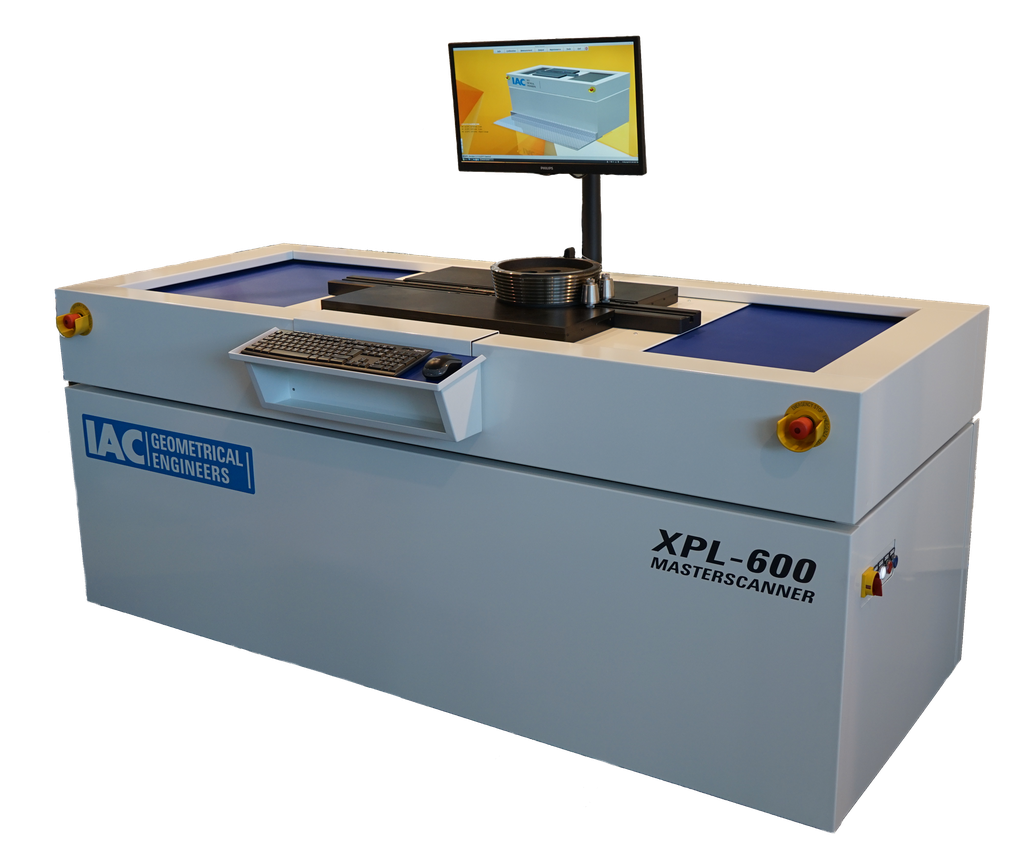

XPL Series

- Campo di misura esterno: 1,0~390/490/590 mm (a seconda del modello)

- Campo di misura interno: 2,5~400/500/600 mm (a seconda del modello)

- Lunghezza di misura massima: 100 mm o 200 mm (a seconda del modello)

- Passo minimo della filettatura: 0,1 mm

- Peso: 1100~1400 kg

- Base in granito

- Guida orizzontale/verticale: Cuscinetto ad aria di precisione

- Tipo di azionamento: Motore brushless svizzero

- Sistema di misura: Sistema di encoder lineare incrementale Heidenhain

- Risoluzione: 0,01 μm

- Scatola di interfaccia con cavi

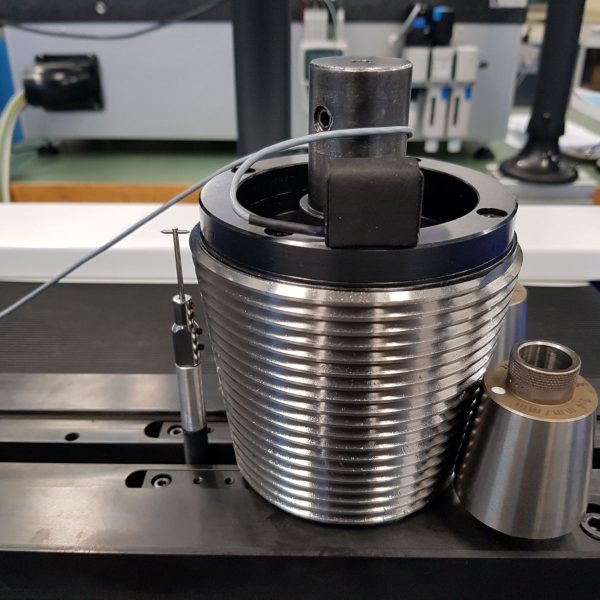

- Sistema di cambio rapido Click'On

- Computer di controllo industriale

- Tastiera, mouse, schermo piatto

- Certificati di calibrazione degli standard acquistati

- Certificati di calibrazione laser degli assi macchina

- Pacchetto software MSProg LINUX (multilingue)

- IACLIB, libreria di tolleranze standard

- 1 anno di garanzia dopo l'accettazione dell'ispezione dal cliente

- 1 anno di aggiornamenti gratuiti di MSProg e dei moduli acquistati

Il contenuto verrà condiviso in tutte le pagine prodotto.

| Max. Scan Length: 200mm / 7.87inch |

| Temperature Compensation: Included |

| Active Anti-Vibration Damping System: Included |

Special manufactured to supply: Gage manufacturers, Oil-, Gas-, Military- and or Aerospace -Industry.

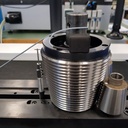

Masterscanner XPL Series Full-automated measurement, without human intervention, the machine displays all measured thread parameters per pitch in under 2 minutes. All measured values are compared with the built-in thread standards library, the system generates the measuring report automatically. The MasterScanner significantly reduces human error, as well as improves the measuring efficiency, quality, consistency and accuracy of the results. The MasterScanner is compliant with all requirements

for tractability of today as stated in ISO-9000 and ISO/IEC 17025:2005.

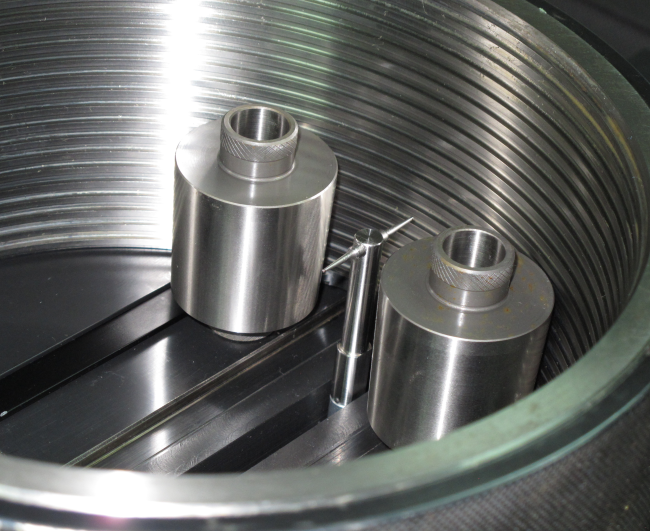

Get all parameters of cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges and other gauges with internal & external dimensions, including virtual pitch diameter , single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half of thread angle, flank straightness, lead angle, taper, perpendicularity, etc.